Endoscope Reprocessing With ENDO

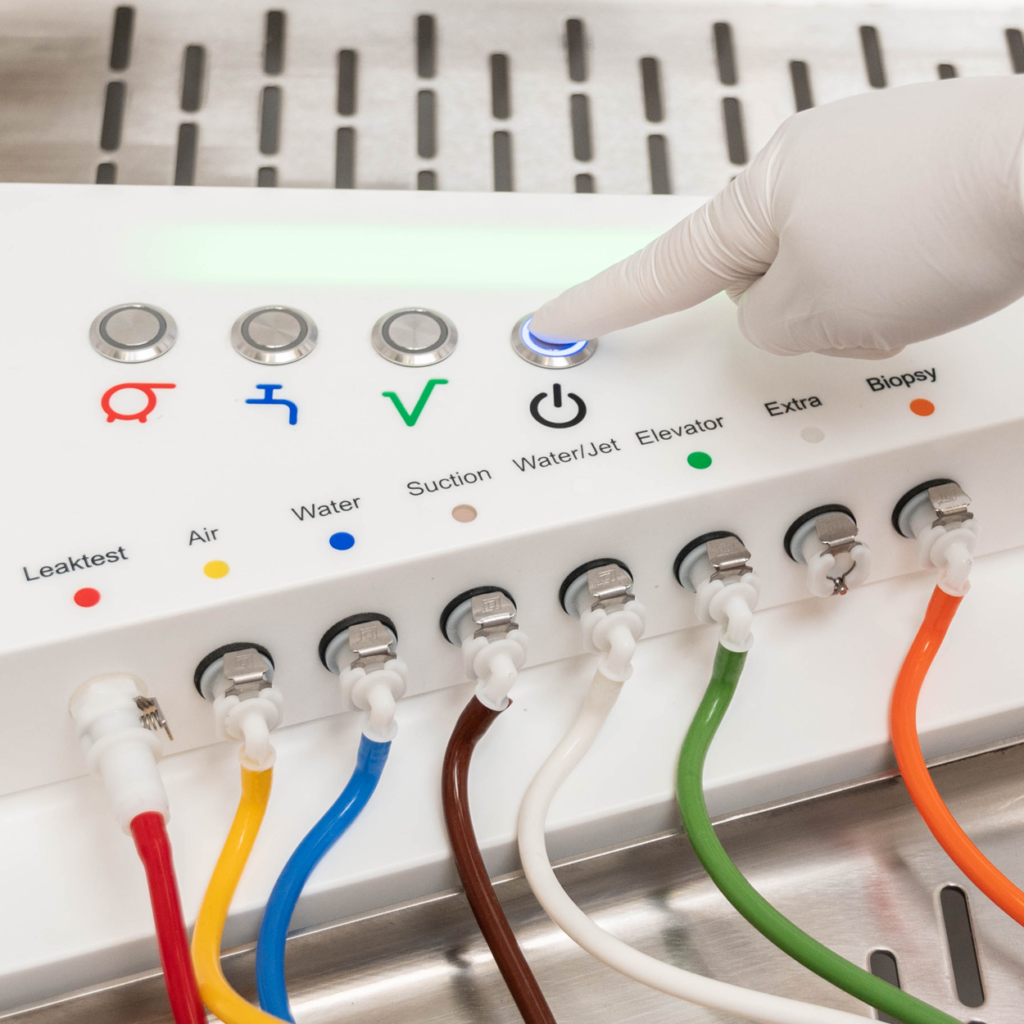

We address early-stage variability with ENDO, an endoscope cleaning device designed to automatically perform and track the full cleaning procedure. By standardizing execution, ENDO reduces the likelihood that critical steps are shortened or skipped under time pressure. The endoscope cleaning reprocessor has camera-assisted recording and built-in track-and-trace so the procedure can be documented and linked to scope history. In daily operations, ENDO functions as a rapid cleaning technology for endoscopes by combining repeatable execution with actionable documentation at the point where workflows are typically most variable.