UltraZonic MED

A new (r)evolution of cleaning surgical instruments

MED

Cleaning surgical instruments in the medical industry is often a compromise. The ultimate goal of infection prevention activities are to minimize the risk of infection before it can happen. Reusable surgical tools must be thoroughly cleaned and decontaminated before they can be successfully sterilized.

These reprocessing steps are crucial. Therefore the capabilities, quality and performance of reprocessing equipment such as washer disinfectors are critical for patient safety. By automating the cleaning cycles, our MED device guarantees that these crucial steps are performed correctly. Procedure after procedure. With thoroughly, yet safely cleaned instruments as a result.

- Powerful

- Safely

- 3-dimensional approach

- Easy to use

- Timesaving

ultrasonic cleaning

Sending ultrasonic waves through the cleaning solution generates hundreds of thousands of small bubbles, induced by high frequency pressure, that grow until they implode. The local cavitations resulting from these implosions function like micro-scrubbers that virtually tear impurities off surfaces.

Since little bubbles are all that implode, this type of cleaning is completely scratch-free and reaches even the smallest cavities that would be impossible to reach by hand or with spray nozzle. All traces of contamination tightly adhering or embedded onto solid surfaces are removed.

Ultrasonic cleaning can be used for a wide range of workpiece shapes, sizes and materials, and may not require the part to be disassembled prior to cleaning.

Objects must not be allowed to rest on the bottom of the device during the cleaning process, because that will prevent cavitation from taking place on the part of the object not in contact with solvent.

differences

Our main goal is to constantly challenge today’s cleaning technologies. Therefore we have improved the traditional ultrasonic cleaning – which hasn’t seen much development over the past 50 years – with new approaches such as frequency modulation, automated degassing, sweeping and skimming.

UltraZonic’s cleaning technology is fast, gentle and extremely powerful. Microscopic cavitation bubbles and specially formulated eco-friendly solutions seek out every crease and crevice, eliminating stubborn or difficult-to-reach contaminants in the process.

handsfree

The MED device thoroughly cleans surgical instruments, all hands free using the following steps:

- Pre-rinsing

- Ultrasonic cleaning

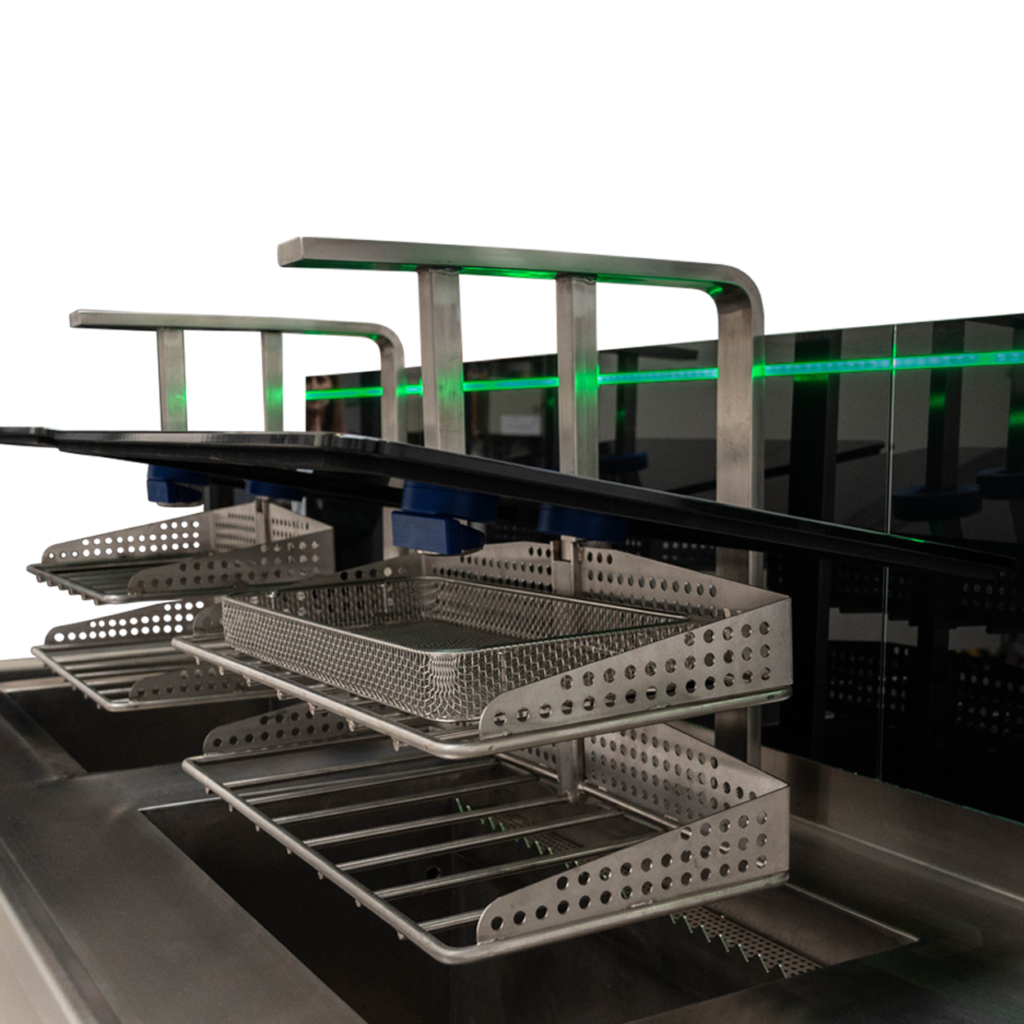

Our Med device is provided with two special racks and integrated channel connections specially designed to intensively clean hollow, surgical instruments:

- 1 rack for Da Vinci instruments

- 1 rack for Luer-lock

This makes sure both internal spaces and external surfaces are thoroughly cleaned, without the risk of damaging them.

unique 3d approach

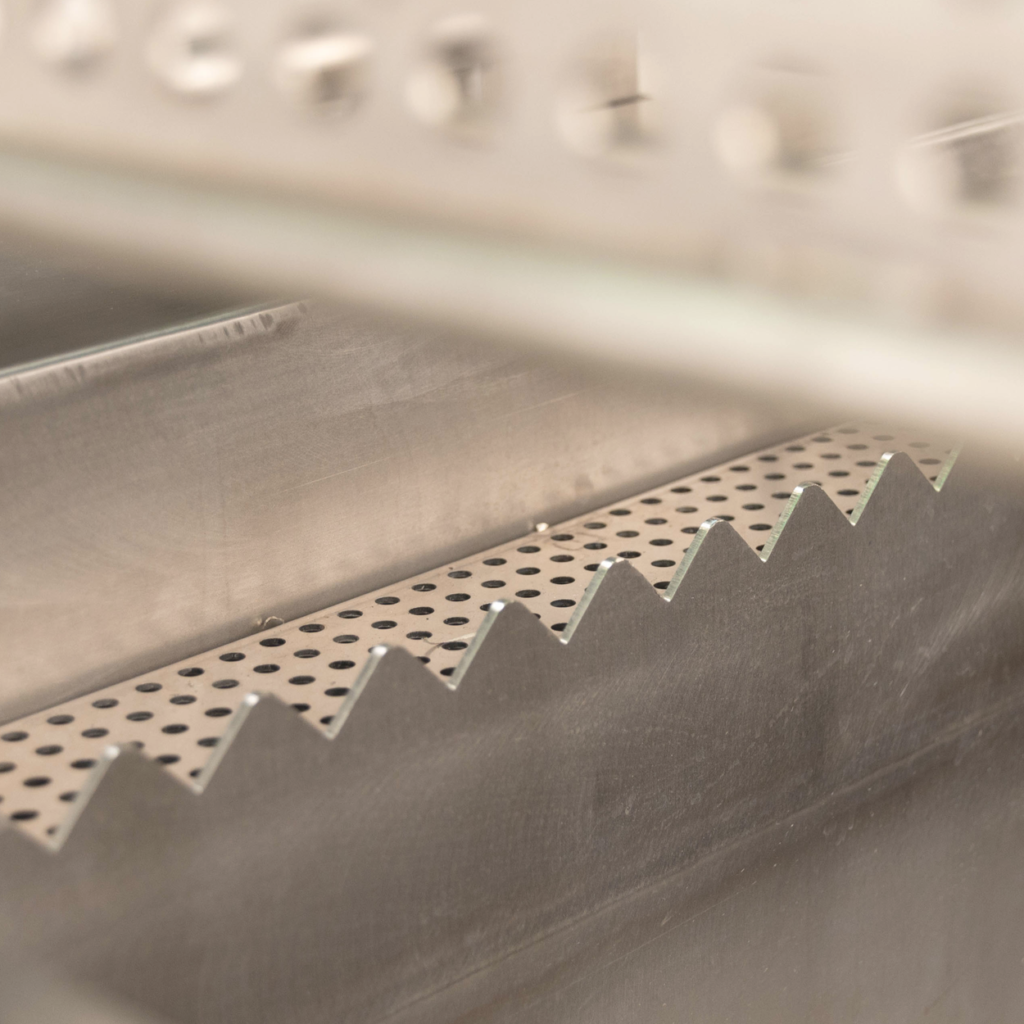

What distinguishes our device from a classic ultrasonic cleaner, apart from the exquisite design, is the patented ultrasonic tank which is equipped with triple-side irradiation. An intensive ultrasonic field is generated like never-seen-before. Extremely efficient and powerful electronics and transducers coupling to ultrasonic bath.

This approach minimizes standing waves and ensures an almost homogeneous ultrasound intensity distribution (no dead zones, no standing waves, no spray shadows). All sides of the instruments are reached by the powerful ultrasonic waves.

advantages

UltraZonic’s state-of-the-art MED-device is manufactured out of stainless steel. The ultrasonic tank itself consist out of the highly qualitive, guaranteeing a sustainable outcome. Its unique to use this type of material for the ultrasonic tank, but the choice was easily made if you prioritize a prolonged operating life of you device.

With our MED, we combine both impeccable design and highest quality material in one device. On top, the pneumatic system enables automatic opening and closing of the covers as well as lifting instruments baskets out of the liquid. Thanks to its easy-to-use touchscreen control panel with height-adjustable arm and platform, work-ergonomics is ensured.

The technology is remarkable, but the process is simple. More efficient and effective than chemical processes, the machines are as simple to use as a dishwasher. Due to an automated pre-rinsing step, no manual intervention or supervision is needed. The MED is equipped with a user-friendly control-panel, guiding the users towards the entire cycle.

Thanks to its unique patented ultrasonic tank, providing triple side irradiation, the use of flexible frequency modulation is possible. This technique ensures the cleaning strength is adjusted to match the requirements of the items being processed. There is a specific frequency approach for each instruments.

By using this technology, there is no risk of damaging highly sensitive instruments (such as Da Vinci and eye surgery) due to wrong frequency approach. Automatically resulting in a prolonged operation life of the instruments.

The efficiency of UltraZonic’s ultrasonic cleaning technology means you save money again and again. The use of cleaning detergents can be significantly reduced, or even eliminated because of the very high cleaning activity of the acoustic broadband spectrum. Time, employees, new purchases due to damaged instruments,.. There is an instant increase in production speed and employee efficiency.

The cleaning time is 70% shorter compared to traditional ultrasonic cleaning technology.

A far superior cleaning technology results in cost and labour time savings. Virtually no employee training is required to operate UltraZonic machines. Even your toughest-to-clean parts and components come out looking brand new. No supervision implies production speed and employee efficiency are increased. Also, no hand wiping is needed to finish the job.

An investment in UltraZonic cleaners means increased patient safety. Rely on UltraZonic microscopic ultrasonic cleaning bubbles and rest assured that contaminants are removed and eliminated from every corner and crevice… quickly, safely and thoroughly.

You will not have to worry about potentially faulty procedures or the possibility of missed build-up in a small groove of an intricate but critical instrument. The advanced software system automatically controls and reports the entire cleaning cycle.

let's talk med

Want more info about this new (r)evolution in Instrument Cleaning?