How to Control Infections in Surgical Instrument Workflows

Effective infection control starts by keeping the roles of cleaning, disinfection, and sterilization clear.

- Cleaning removes soil so later stages can work as intended

- Disinfection reduces microbial load but does not compensate for retained debris

- Sterilization targets microorganisms but is compromised by residual contamination on instrument surfaces.

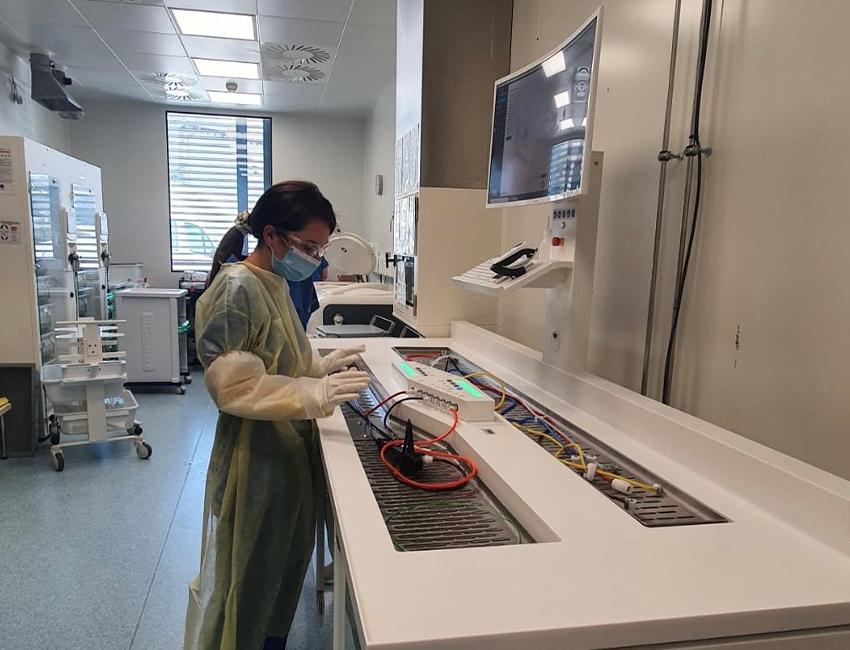

In practice, automated pre-treatment for surgical instruments can reduce early-stage variability by standardizing timing, handling, and key parameters before washer-disinfector cycles. Verification matters as much as execution, documented pass/fail checks and traceability make it possible to audit compliance and investigate deviations. In some workflows artificial intelligence can support review by flagging inconsistencies in recorded evidence and documentation.